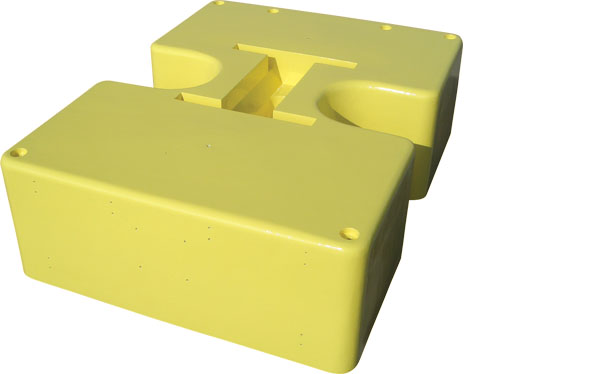

Uncoated this closed-cell polyurethane foam has been tested to depths of 1200 ft. Modules are custom-designed to fit each application taking into consideration the designed uplift pipeline specifications and deployment strategy.

Marine Foam Of Buoyancy Material Rovmaker

Marine Foam Of Buoyancy Material Rovmaker

Using innovative and advanced in-house developed syntactic foam materials technology and manufacturing processes BMTI delivers optimal performance in subsea products for deepwater applications.

Subsea buoyancy foam. This foam can be machined glued painted and coated to build any size or shape of float that you want. From shallow water PU foam solutions to robust range of innovative deepwater syntactic foam products Advanced Insulation leads the market with the lowest achievable foam densities and next generation efficient designs. Subsea Buoyancy Foam for use on ROVs AUVs and other marine robotics applications.

This foam can be machined glued painted and coated to build any size or shape of float that you want. Advanced Insulations range of subsea installation buoys are designed to provide a general purpose solution to subsea buoyancy. R-3312 Subsea Buoyancy Foam for use on ROVs AUVs and other marine robotics applications.

SynFoam for subsea buoyancy is typically sold as pre-cast blocks that measure 6 x 12 x 24 inches. Subsea Buoyancy Foam for use on ROVs AUVs and other marine robotics applications. 10 - 14 business days.

This subsea polyurethane foam supports training operations for the International Space Station providing buoyancy for assembly components in pools that simulate weightlessness. Our own formulations and associated manufacturing processes testing throughout the production chain low. Available in two standard sizes.

Up for auction is this SUBSEA MK-150 Strobe Light for Underwater Photography as used by SCUBA Divers. And might compliment a Nikonos camera outfit. 10 - 14 business days.

This foam can be machined glued painted and coated to build any size or shape of float that you want. Syntactic foam core - each half of the buoyancy element has a composite syntactic foam core the properties of which can be adjusted to suit the full range of seawater depths from 100msw to 6000msw and beyond Polymer external skin - the syntactic foam core is fully encapsulated within a high performance polymer external skin to. We offer the smartest buoyancy solutions.

Subsea Buoyancy Foam 1000 EGP 10100 EGP Subsea Buoyancy Foam for use on ROVs AUVs and other marine robotics applications. 100kg and 500kg water depth ratings between 250MSW and 3000MSW are available. Buckle Mitigation Buoyancy is used to protect subsea pipelines on the seafloor from the effects of lateral buckling.

This foam can be machined glued painted and coated to build any size or shape of float that you want. We create subsea buoyancy products for oceanographic offshore oil gas and technology companies around the world. Though SynFoam is easily machined many customers rely on us for the complete assembly of the required buoyancy module.

In floating production scenarios buoyancy is used to configure subsea systems mitigating unwanted loads and stresses. General Plastics supplies hydrostatic pressure-resistant subsea foam for use in subsea mooring buoyancy semi-submersible craft pipeline flotation underwater robotics ROVAUVs and more. Note the 19 x 34 x 49 in block is used on the BlueROV2 to provide buoyancy.

Strobe looks like it could illuminate a whole reef. Customers have relied on our products for over forty years from the ocean surface to depths exceeding six thousand meters.