Acoustic emission testing is not only ideal for localising cracks and leakage and for identifying corrosion and faults. The acoustic emission testing market will grow at a rate of 745 in the forecast period of 2020 to 2027.

Nondestructive Evaluation Techniques Acoustic Emission Testing

Nondestructive Evaluation Techniques Acoustic Emission Testing

The technology of acoustic emission AE testing has been advanced and used at Sandia for the past 40 years.

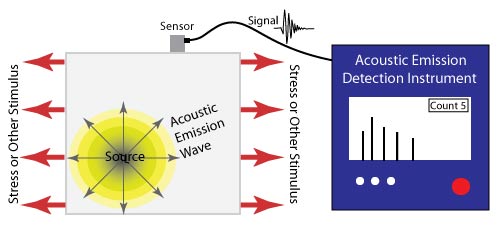

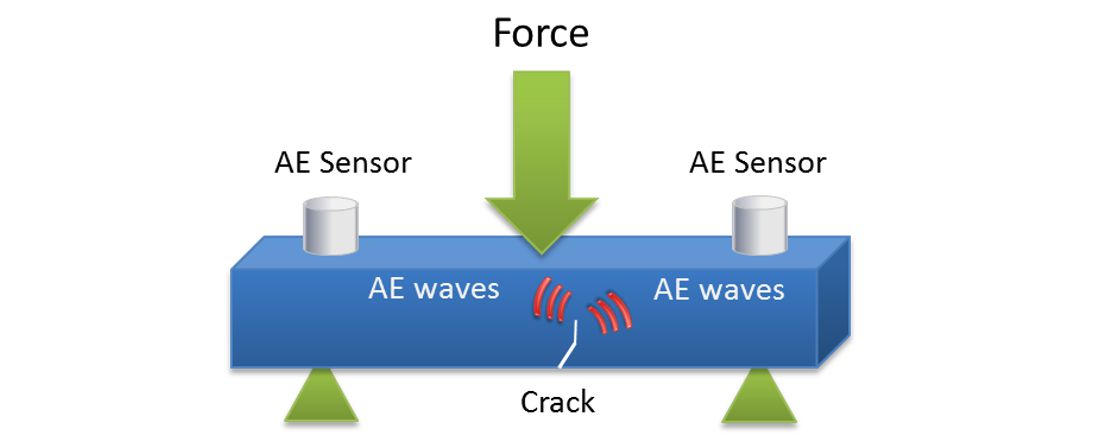

Acoustic emission testing. Overview of Acoustic Emission Testing AET Acoustic Emission Testing AET is a nondestructive testing NDT method that is based on the generation of waves produced by a sudden redistribution of stress in a material. Acoustic Emission AE testing is a powerful method for examining behavior of materials deforming under stress. Acoustic Emission AE Testing.

Acoustic emission testing AET is a non-destructive test NDT method that reliably recognises impending problems and defects before they become serious. The efforts continue and the first European training course in acoustic. Acoustic Emission AE refers to the generation of transient elastic waves produced by a sudden redistribution of stress in a material.

Acoustic Emission Testing AET is a Non-Destructive Testing NDT method that is used to analyse emitted sound waves caused by defects or discontinuities. Accepted as a standardised NDT method although Acoustic Emission Testing AT was mentioned under all NDT methods for which the rules of EN 473 could be used. These acoustic waves are induced by small deformations corrosion or cracking which occur prior to structure failure.

FUntil about 1973 acoustic emission technology was primarily employed in the non-destructive testing of such structures as pipelines heat exchangers storage tanks pressure vessels and coolant circuits of nuclear reactor plants. Acoustic Emission Testing AT Grundlagen Verfahren und praktische Anwendung Version 2018 Zielstellung Messprinzip Art der Prüfung AT-Messtechnik Aufzeichnung und Analyse von AE-Daten AT-Messgrößen Auswertung der AE-Daten Zuverlässigkeit der. Acoustic emission AE is used widely in non-destructive evaluationstructural health moni-toring to detect the presence of dangerous flaws and to locate the positions of such flaws in struc- tures of various kinds.

Through AE testing MISTRAS listens to the sounds of cracks growing fibers breaking and many other modes of active damage in stressed materials. There are three principal phases involved. Acoustic Emission AE testing is a powerful method for inspecting and monitoring the behavior of equipment and materials performing under stress.

The techniques are recently going to be more and more applied to practical applications and to. This decision was a considerable setback for the efforts to establish a common European and comparable training for AE. Data Bridge Market Research report acoustic emission testing market provides analysis and insights regarding the various factors expected to be prevalent.

AET is a type of nondestructive test NDT that has various uses including ensuring the structural. Acoustic emission testing requires a minimum of three acoustic emission sensors installed on the outside of the structure via rope access to locate expanding defects by triangularly detecting the acoustic waves being emitted. It is therefore possible with AET to locate structural defects and to.

Acoustic Emission AE techniques have been studied in civil engineering for a long time. AE has been used on structures including pressure vessels fire bottles wind turbines gas wells nuclear weapons and solar collectors. During the second half of the 20th century AE from materials especially AE from defor-mation and.

When a structure is subjected to an external stimulus change in pressure load or temperature localized sources trigger the release of energy in the form of stress waves which. Flaw origination and progression in a stressed component can be identified by acoustic emission test methodThis can be done when the component is subjected to repetitive or continuous stress. Acoustic Emission Testing A cost-saving method to inspect pressure vessels.

If playback doesnt begin shortly try restarting your. Materials talk when they are in trouble. Acoustic emission testing is often performed parallel to the Hydro-test.

Acoustic Emission Test is a type of Non Destructive Test method generally used for detecting and locating imperfections in mechanically loaded structures or components. The Acoustic Emission NDT technique is based on the detection and conversion of high frequency elastic waves into electrical signals. When a piece of equipment is subjected to an external stimulus such as a change in pressure load or temperature this triggers.

It is also indispensable for the investigation of dynamic behavior of mate-rials. The term acoustic emission testing AET refers to the process of detecting and recording AE using specialized equipment. Acoustic emission may be described as the sound emanating from regions of localized deformation within a material.

Acoustic emission is a type of procedure that is being used increasingly in the field of structural integrity assessment using. What is Acoustic Emission Testing.